What is a Power Press Machine, it uses benefits and safety?

What is a Power Press Machine?

A Power Press Machine is a mechanical device used to shape, cut, bend, and form metal sheets with high precision and efficiency. It plays a crucial role in various sheet metal fabrication processes, making it indispensable in modern manufacturing. This highly versatile tool performs both forming and cutting of metals simultaneously, ensuring faster production cycles and improved accuracy.

It’s one of the most adaptable sheet metal machines on the market, and it’s employed in a variety of heavy industrial applications. Previously, manually shaping the metal sheet required a considerable deal of labor and force. But with the help of a Power press , it will be easier to cut, bend, press, and form the metal sheet into different shapes and sizes by applying a high amount of pressure.

Explore Our Full Range of Power Press Machines Today!

Power Press Machine Working:

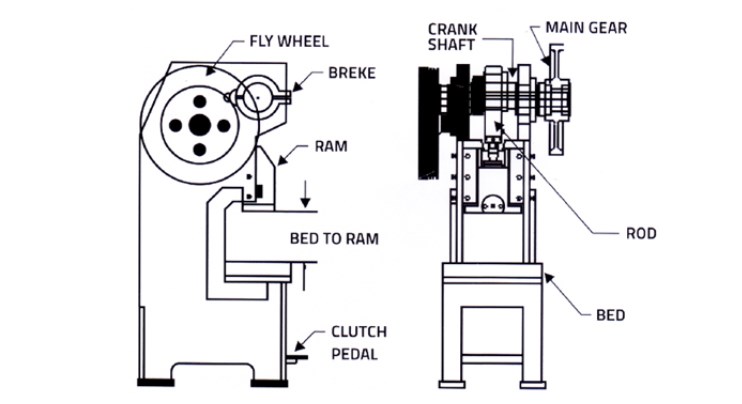

The Power Press converts circular motion into linear motion through its design. Its major components include the clutch, flywheel, crankshaft, stationary ram, and moving ram.

Major parts of the Power Press :

Base:

The base is the supporting member of the press and provides arrangements for tilting and clamping the frame in an inclined press.

Ram:

Ram reciprocates to and fro within its guideways which prescribes stroke length and power. The stroke length and power transferred can be adjusted as per the requirements. The ram at its bottom end carries a punch to process the workpiece.

Flywheel:

The flywheel is mounted at the edge of the driving shaft and is connected to it through a clutch. The energy is stored up in the flywheel during idle periods and it is expected to maintain the constant speed of the ram when the punch is pressed into the work.

Clutch:

The clutch is used to connect and disconnect the driving shaft with the flywheel when it is necessary to start or stop the movement of the ram.

Brakes:

The brakes are used to stop the movement of the driving shaft immediately after it is disconnected from the flywheel.

Working Principle :

The ram and bed of the Power Press Machine are equipped with combination dies to shape metal sheets. A motor powers the rotation of the flywheel, which connects to the crankshaft through a clutch. The crankshaft converts the flywheel’s rotational motion into the ram’s upward and downward motion.

A workpiece is fed to the die, and the tool cycle begins. The upper and lower dies press together on the stock material, creating a re-formed piece. After completing the downstroke, the operator removes the finished piece and replaces it with a new one to repeat the process.

Types of Power Press Machines:

C-Type Power Press Machines:

Known for their C-shaped frame, these machines provide excellent accessibility and are commonly used for operations like punching, stamping, and bending.

H-Type Power Press Machines:

Designed with an H-shaped frame, these machines offer higher stability and strength, suitable for heavy-duty applications.

Hydraulic Power Press Machines:

Utilizing hydraulic cylinders to generate force, these machines provide precise control over the pressing process and are ideal for complex shaping tasks.

Applications of Power Press Machines:

Power Press Machines are widely used across various industries due to their efficiency and versatility. Key applications include:

- Automotive Industry: Manufacturing car body parts, chassis, and other components.

- Agriculture: Producing farming equipment and machinery parts.

- Electrical Industry: Fabricating components for electrical enclosures and devices.

- Aerospace: Shaping lightweight and durable parts for aircraft.

- General Engineering: Used in various metal fabrication tasks across engineering sectors.

What are the Uses of Power Press?

- These machines are widely used in heavy manufacturing industries, including factories and engineering plants.

- Power press is a must-needed machine for the automobile, agriculture, bicycling, engineering, and electrical sectors.

- C-type power presses and hydraulic power presses are commonly used due to their efficiency.

- It is used as a workplace machine because of its simplified metal bending operations.

What are the benefits of Power Press Machines?

- Increased Efficiency: Automates metal cutting and shaping processes, reducing manual labor and production time.

- Cost-Effective: Offers a low power press machine price with minimal maintenance costs.

- Versatility: Capable of performing multiple operations like punching, bending, and forming.

- Precision and Consistency: Ensures uniformity in production with accurate metal shaping.

- Durability: Built to withstand heavy-duty industrial use with minimal upkeep.

Safety Measures While Using a Power Press Machine :

- If you own a power press at your workshop people handling it must have the proper knowledge and skills about the working of the machine.

- The appointed person is to be trained before operating the machines because that is the person who is responsible for maintaining them.

- One can also make some written notes on the working of the machine that will be helpful for the person to easily know about the machine.

- It is necessary to check the working of the machine regularly to use it safely.

- The components used in the machine can be regularly checked by a knowledgeable person.

- Maintain proper records of power press maintenance activities to schedule servicing.

- When the machine is not in use, the power of the machine should be switched off

Price Of Power Press Machine :

The Rajesh Machine stands out for its quality and price. It caters to various industrial applications, offering a range of machines, including 10-ton, 20-ton, 30-ton, and more. Rajesh Machine Tools manufactures, supplies, and exports high-quality hydraulic press machines. For affordable power press machine prices, feel free to contact us.

Conclusion:

If you are looking for high-quality Power Press Machines, Rajesh Machines are the best choice. Rajesh Machine Tools is a trusted name in power press manufacturing, offering a wide range of products, including hydraulic power presses, C-type power presses, press brake machines, high-power press machines, and shearing machines across India. Choose Rajesh for reliable and efficient industrial machines.

FAQ'S

A power press machine is a mechanical device used for cutting, bending, pressing, and shaping metal by applying pressure. It utilizes various dies and tools to transform metal sheets into desired shapes and forms.

The power press machine working process involves converting circular motion into linear motion using components like the flywheel, clutch, and crankshaft. The ram applies pressure to a metal sheet placed between a die and a punch, forming or cutting it into the desired shape.

There are several types, including:

- Mechanical press machines, which rely on flywheels for power.

- Hydraulic power presses, which use hydraulic cylinders for operation.

- C-type power presses, known for their compact and sturdy design.

Power press machines are widely used in automotive, aerospace, electronics, and construction industries for fabricating parts like car panels, brackets, and metal enclosures.

These machines primarily process metal sheets but can also work with plastics and other materials, depending on the die and punch used. Models like the 10-ton power press machine and 20-ton power press machine are ideal for various applications.

- Have any Query?