What are Press Brakes, Its working, Types, Applications, and Advantages?

Press brakes are must-have machines in your workshops. Their durability and versatility make them unique. All machines have different specialties for sheet metal forming and bending, and press brakes are also used to bend even tiny pieces of sheet metal. One of the well-known machines is the Press Brakes.

What are Press Brakes?

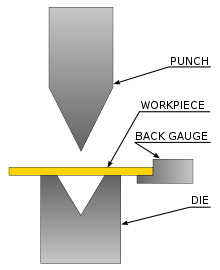

Press Brake is the machine that is specially used for bending sheet metal. The capability of the machines is significant by the two factors: The overall bending length and their capacity to bend metal. The press brake is narrow and long in size so that any size of sheet metal can be bent easily. By lowering a punch into sheet metal that has been positioned on top of a die, a press brake bends sheet metal. A press brake may bend the metal multiple times until it reaches the required shape.

Working of Press Brakes :

While the Brakes have many different essential parts, they are :

- Punch – the tool that bends the workpieces by “punching” them into the die.

- Workpiece – The surface on which the material is placed and the bend is applied.

- Die – The tool that allows the workpiece to bend.

Types of Press Brakes :

Bending sheet metal necessitates a great deal of force, and the punch is dropped onto the sheet metal in various ways to acquire and apply this force. Modern machines require less effort than the older ones.

The following are the main types of Press brakes according to the different Operations:

Mechanical Press Brakes :

These are the most common types of brakes. Mechanical is operated using the motor inside them. A motor gives energy to the flywheel and spins a large flywheel at high speed. The machine operator controls the flywheel through a clutch. The mechanical press brake is simpler, especially in terms of its electronics. It makes maintenance and operation much more effortless. The mechanical press brakes can handle tons up to three times their intrinsic rating. This machine has one major drawback: the ram must go through a complete cycle once engaged. One potential danger is that the press brake could become locked if too much RAM travels.

Hydraulic Press Brakes:

Hydraulic press brakes use pressure to push the ram down instead of mechanics. They can have multiple cylinders, which gives the operator greater control over the bend. This results in a bend that is highly customizable and precise. This machine has certain disadvantages. They cannot exceed their rated tonnage. Mechanical press brakes are a good choice if your project is flexible.

CNC Press Brakes :

These brakes are highly customizable and precise, and they use computer technology to increase efficiency and control accuracy. A trained operator can input data like bending angle, plate thickness, and width into a controller to control the brake and then handle the rest.

At Rajesh Group, we provide all these three types of machines.

Applications of Press Brakes :

- Automotive

- Aerospace

- Furniture

- Marine Engineering

- Metal artwork

- Metal containers

- Other sheet metal applications

Advantages Of Press Brakes:

1. More Flexible :

Unlike the other machines, these machines are used for bending a small part to significant amounts of metals. It is suitable for any size of sheet metals2. Reducing Material Waste:

Unlike other equipment that uses many materials to create the products you desire, the machine can boost high-end precision and accuracy. Additionally, it means less waste of materials.3. Low cost :

The cost of the dies used in the machine is low, and the service life is very long.4. Complete both Production “S” and “U”:

In these two types, the stamping of the “U” moulding is more complicated. With the help of the Press Brake, both mouldings are possible.5. Forming of Prototypes:

One of the most fundamental advantages of this machine is its ease of setup and tooling. Switching between apps is a breeze due to this, and it also simplifies the process of prototyping bedding and shaping applications.In the end, press brakes are the must-have machines used in the sheet metal industry to easily bend metal into various shapes and sizes. They are as important as the power press and the shearing machines.