NC Swing Beam Shearing Machine

NC Swing Beam Shearing Machine

Standard Equipment

- Multi Edge Blades for Cutting Aluminium, Carbon Steel & Stainless Steel

- Cutting Line Illumination and wire for shadow line cutting

- Stroke Counter

- Quick Cutting Length Adjustment

- Hydraulic and Electrical Overload Protection

- Squaring ARM and Front Support ARM

- Beed Infill Plates with Ball Transfers

- Delta Inverter with Ball Screw and Polished Rod with 0.01 mm

- AccuracyDelta Inverter with Ball Screw and Polished Rod with 0.01 mm Accuracy

- Back Gauge Adjustment According to Blade Gap

- Back Gauge Retraction Features

- Sub Program and Programming Loop

- Sequence Repeat Function

- Auto Cutting (Flying Cut)

Optional Equipment

- Delem DAC 310 CNC Controller

- ELG0 P40 Controller

- Pneumatic Sheet Supporing System

- Table Mounted Sheet Angle Cutting Guage

Rear safety guard

1000mm sliding front Arms and finger Protection system

Germany Bosch-Rexrith Hydraulic System

Schneider Electrical from French

Estun E21S NC System

Estun E21S NC System

Front Sheet Support with Right Angle

Rear Sheet Support

Photo safety curtain

ESTUN E200-S

- Program Memory up to 40 Program up to 25 Steps Per Program

- One Side Positioning Indication

- Retract Funcation

- Auto Reference Search

- Power Down Memorization mm/inch

- English Diagnoses Function

DELEM DAC310

- Servo control technology

- Bright LCD display, 128×64 pixels

- Back gauge, Gap or Angle control

- Stroke length limitation

- Actual and programmed position visualisation

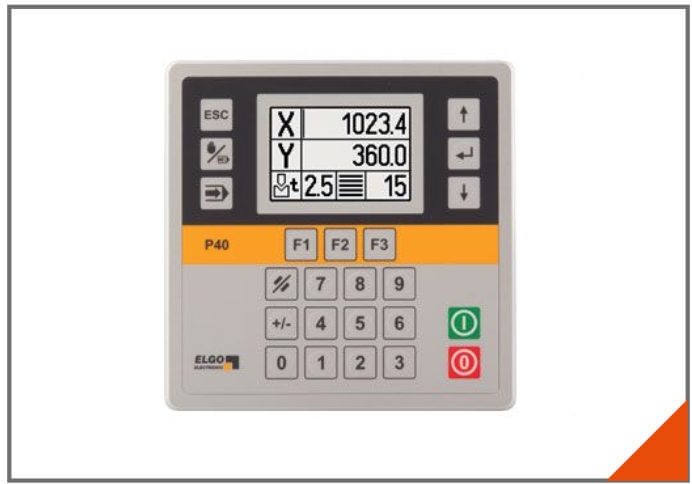

ELGO P40

- Single or Two axis Controller

- LCD display

- Manual function

- Single set operation

- Program set operation

- Digital Output

- Analog Output

FRAME CONSTRUCTION

Swing Beam Shearing Machine fabricated from IS-2062 graded rolled steel plates table and cutting beam are deeply reinforced and fines shearing machines after stress reliving. The interlocked design put the direct support to frame. This frame is strain free and eliminates welds at load supports. Thus the accuracy of the shearing machine is never disturbed.

TABLE

Super strong table of closed box type construction. Stress relived in a furnace. Forms a rigid backbone for the shear and a solid backing for the lower knife.

UPPER BEAM

Upper beam is also of solid steel plate, carrying the upper knife. Its minimum weight ensures lesser load on the roller. The upper beam moves in flat heat-treated steel guide plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife.

HOLD-DOWN

Solid clamping by powerful hydraulic loaded hold-down is one of the reasons for accuracy in our shearing machine. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of variations in thickness. Hold-down pressure is easily adjustable for clamping soft material. Different thickness of the material can be cut without further adjustment with consistently accurate and burr free results.

BLADE (Knife)

Knifes are manufactured strictly as per standard HCHCr/OHNS. Every step from designing metallurgical specification, heat-treatment grinding and inspection is carefully controlled. The blades are standardized and are easily replaced.

CYLINDER

The cylinder bodies are precisely made from forged steel material duly bored and fine honed for long sealing life. The piston rods are made From EN – 8 material having low carbon contents. The piston rod is hard chrome platted (0.200 micron).

HYDRAULIC SYSTEM

The compact Blocks eliminate the leakage chances and also reduces the hydraulic pipes. This low Noise hydraulic system is placed on the rear side of shearing machine, on top between two side plates. Pressure relief value is provided to safe guard the system and shearing machine from overload. The hydraulic system is driven by an electric motor of reputed brand and is coupled with a pump capable of generating more than the required pressure in shearing machine. Pressure gauge for system pressure, backpressure and holding pressure are providing on top of oil tank for quick reference.

ELECTRONIC CONTROL PANEL

The electric control panel is located on the left hand side of the shearing machine. It is assembled from the internationally reputed parts for consistent performance, reliability and availability, if needed to be replaced. It is wired cleanly and labelled/ferruled properly as per the international practices to help easily locate any fault and replace components conveniently.

ACCURATE GAUGING

The rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheet being cut.

Technical Parameters

Model No. | Cutting Thickness | Cutting Width | Cutting Angle | Material Intension kN*m | Backgauge Range | Number of Stroke | Number of Hold Down | Main Motor kW | Weight Kgs | Overall Dimension Length x Width x Height |

|---|---|---|---|---|---|---|---|---|---|---|

| RP-Cut S - 2504 | 4 | 2500 | 1°30′ | 450 | 20-500 | 10 | 12 | 5.5 | 3800 | 3040x1610x1620 |

| RP-Cut S - 3204 | 4 | 3200 | 1°30′ | 450 | 20-500 | 10 | 14 | 5.5 | 5000 | 3840x1610x1620 |

| RP-Cut S - 4004 | 4 | 4000 | 1°30′ | 450 | 20-750 | 8 | 16 | 5.5 | 6500 | 4600x1700x1700 |

| RP-Cut S - 6004 | 4 | 6000 | 1°30′ | 450 | 20-750 | 5 | 20 | 7.5 | 11000 | 6460x2100x3200 |

| RP-Cut S - 2506 | 6 | 2500 | 1°30′ | 450 | 20-500 | 10 | 12 | 7.5 | 5000 | 3040x1610x1620 |

| RP-Cut S - 3206 | 6 | 3200 | 1°30′ | 450 | 20-750 | 9 | 14 | 7.5 | 6000 | 3840x1610x1620 |

| RP-Cut S - 4006 | 6 | 4000 | 1°30′ | 450 | 20-750 | 8 | 16 | 7.5 | 8200 | 4620x1750x1700 |

| RP-Cut S - 5006 | 6 | 5000 | 1°30′ | 450 | 20-750 | 6 | 18 | 7.5 | 10500 | 5400x1800x1900 |

| RP-Cut S - 6006 | 6 | 6000 | 1°30′ | 450 | 20-750 | 5 | 20 | 11 | 16500 | 6480x2100x2300 |

| RP-Cut S - 2508 | 8 | 2500 | 1°30′ | 450 | 20-750 | 10 | 12 | 7.5 | 6000 | 3040x1700x1700 |

| RP-Cut S - 3208 | 8 | 3200 | 1°30′ | 450 | 20-750 | 8 | 14 | 7.5 | 7200 | 3860x1700x1700 |

| RP-Cut S - 4008 | 8 | 4000 | 1°30′ | 450 | 20-750 | 8 | 16 | 7.5 | 8800 | 4640x1700x1700 |

| RP-Cut S - 5008 | 8 | 5000 | 1°30′ | 450 | 20-750 | 8 | 18 | 7.5 | 11500 | 5400x2100x2000 |

| RP-Cut S - 6008 | 8 | 6000 | 1°30′ | 450 | 20-750 | 8 | 20 | 11 | 18000 | 6480x2100x2350 |

| RP-Cut S - 2510 | 10 | 2500 | 2° | 450 | 20-750 | 9 | 12 | 11 | 7300 | 3040x1700x1700 |

| RP-Cut S - 3210 | 10 | 3200 | 2° | 450 | 20-750 | 9 | 14 | 11 | 8000 | 3860x1700x1700 |

| RP-Cut S - 4010 | 10 | 4000 | 2° | 450 | 20-750 | 8 | 16 | 11 | 12050 | 4650x2100x2000 |

| RP-Cut S - 6010 | 10 | 6000 | 2° | 450 | 20-750 | 5 | 20 | 15 | 24000 | 6500x2100x2300 |

| RP-Cut S - 2512 | 12 | 2500 | 1°40′ | 450 | 20-750 | 9 | 12 | 18.5 | 9000 | 3140x2150x2000 |

| RP-Cut S - 3212 | 12 | 3200 | 1°40′ | 450 | 20-750 | 9 | 14 | 18.5 | 10800 | 3880x2150x2000 |

| RP-Cut S - 4012 | 12 | 4000 | 1°40′ | 450 | 20-750 | 8 | 16 | 18.5 | 13000 | 4680x2150x2000 |

| RP-Cut S - 5012 | 12 | 5000 | 2° | 450 | 20-750 | 6 | 18 | 18.5 | 16000 | 5900x2150x2000 |

| RP-Cut S - 6012 | 12 | 6000 | 2° | 450 | 20-1000 | 5 | 20 | 18.5 | 29500 | 6900x2600x2700 |

| RP-Cut S - 8012 | 12 | 8000 | 2° | 450 | 20-1000 | 5 | 24 | 18.5 | 46500 | 9000x3500x3500 |

| RP-Cut S - 2516 | 16 | 2500 | 2°30′ | 450 | 20-750 | 9 | 12 | 18.5 | 11000 | 3140x2150x2000 |

| RP-Cut S - 3216 | 16 | 3200 | 2°30′ | 450 | 20-750 | 8 | 14 | 18.5 | 13000 | 3880x2150x2000 |

| RP-Cut S - 4016 | 16 | 4000 | 2°30′ | 450 | 20-750 | 8 | 16 | 18.5 | 16300 | 4650x2150x2000 |

| RP-Cut S - 5016 | 16 | 5000 | 2°30′ | 450 | 20-1000 | 6 | 18 | 18.5 | 20000 | 5900x2600x2700 |

| RP-Cut S - 6016 | 16 | 6000 | 2°30′ | 450 | 20-1000 | 5 | 20 | 22 | 36000 | 6900x2700x2700 |

| RP-Cut S - 8016 | 16 | 8000 | 2°30′ | 450 | 20-1000 | 5 | 24 | 22 | 75000 | 9000x3500x3500 |

| RP-Cut S - 2520 | 20 | 2500 | 3° | 450 | 20-750 | 8 | 12 | 22 | 15800 | 3440x2300x2500 |

| RP-Cut S - 3220 | 20 | 3200 | 3° | 450 | 20-1000 | 8 | 14 | 22 | 18500 | 4150x2350x2700 |

| RP-Cut S - 4020 | 20 | 4000 | 3° | 450 | 20-1000 | 5 | 16 | 22 | 21500 | 4850x2600x2700 |

| RP-Cut S - 6020 | 20 | 6000 | 3° | 450 | 20-1000 | 4 | 20 | 22 | 47000 | 6700x3000x3000 |

| RP-Cut S - 2525 | 25 | 2500 | 3° | 450 | 20-1000 | 8 | 12 | 37 | 19000 | 3200x2700x2900 |

| RP-Cut S - 3225 | 25 | 3200 | 3° | 450 | 20-1000 | 5 | 14 | 37 | 23000 | 4200x2900x3200 |

| RP-Cut S - 2530 | 30 | 2500 | 3° | 450 | 20-1000 | 4 | 12 | 37 | 23500 | 3300x2900x3000 |

| RP-Cut S - 3230 | 30 | 3200 | 3°30′ | 450 | 20-1000 | 4 | 14 | 40 | 26000 | 4200x2900x3200 |

| RP-Cut S - 2540 | 40 | 2500 | 4° | 450 | 20-1000 | 3 | 12 | 75 | 38000 | 3200x3300x3000 |

| RP-Cut S - 3240 | 40 | 3200 | 4° | 450 | 20-1000 | 3 | 14 | 90 | 49000 | 4300x3300x3200 |

*All dimensions are in mm

- Have any Query?